Natcore’s highly specialized laser processing will eliminate a second, final furnace, cutting costs even further.Natcore’s black silicon process should save 23.5% in manufacturing costs by eliminating one furnace from the conventional production process.The all-back-contact cell is the latest salvo in Natcore’s assault on solar cell manufacturing costs. It will provide the best of all worlds by allowing high-performance all-back contact cells to be manufactured at much lower cost than current or conventional solar cells. Natcore’s elegantly simple approach makes it uniquely suited to large-scale manufacturing. Natcore’s all-back-contact cell, on the other hand, uses only high-speed, inexpensive laser processing to define the doping regions and the contacts. While other all-back-contact cells have been produced, they use high-temperature diffusion in their doping steps and highly complex multi-step patterning processes to apply the electrical contacts. These and other performance metrics indicate that, with further refinement, efficiencies significantly equaling or exceeding today’s best commercial cells are possible. Moreover, in their latest effort the Natcore team has achieved an open-circuit voltage of 0.6 V. This increase along with other expected gains can increase efficiencies by up to 4% on an absolute basis relative to current benchmarks for front contact solar cells. Working in their R&D Center in Rochester, NY, the Natcore team has successfully used their proprietary advances in laser technology to produce an all-low-temperature laser-doped solar cell with all of its electrical contacts on the back of the cell.Įliminating the contacts from the front of the cell will allow an additional 4% to 6% more light to enter the cell and increase its output by a comparable amount. Now Natcore’s scientists have taken a giant step further, with an advance that promises not only to slash production costs, but also add significantly greater power output to commercial solar cells.

Red Bank, NJ - (January 27, 2015) -Three months ago, Natcore Technology ( TSX-V: NXT NTCXF.PK) announced that its scientists had created an all-low-temperature, laser-processed solar cell. 8.Will allow high-performance, all-back-contact solar cells to be manufactured at much lower cost than conventional cells.Mismatch for Cells Connected in Parallel.

ALL BACK CONTACT SOLARCELL SERIES

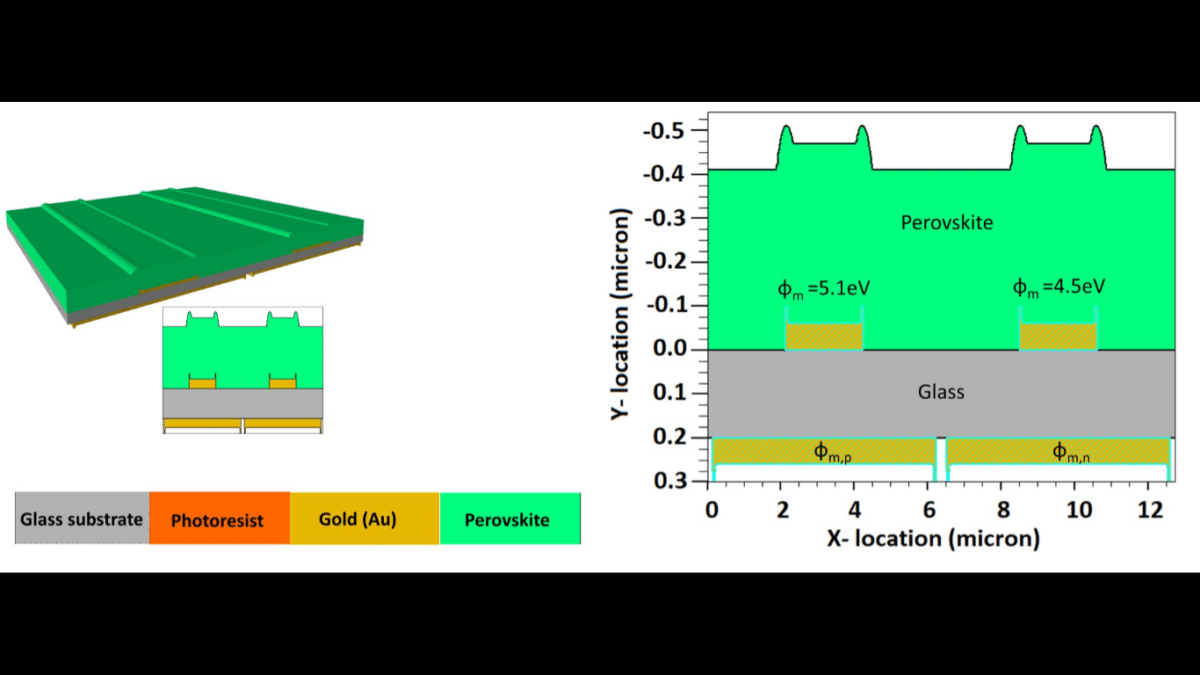

Impact of Both Series and Shunt Resistance.Applying the Basic Equations to a PN Junction.Solar Radiation Outside the Earth's Atmosphere.A., “ 7000 High Efficiency Cells for a Dream”, Progress in Photovoltaics: Research and Applications, vol. Such cells are especially useful in concentrator applications where the effect of cell series resistance is greater.Īn additional benefit is that cells with both contacts on the rear are easier to interconnect and can be placed closer together in the module since there is no need for a space between the cells.īack Contact Solar Cell as used in commercial production. By using a thin solar cell made from high quality material, electron-hole pairs generated by light that is absorbed at the front surface can still be collected at the rear of the cell 1.

Rear contact solar cells eliminate shading losses altogether by putting both contacts on the rear of the cell. Interdigitated back contact solar cells (IBC) The higher efficiency potentially results from the reduced shading on the front of the cell and is especially useful in high current cells such as concentrators or large areas. Rear contact solar cells achieve potentially higher efficiency by moving all or part of the front contact grids to the rear of the device.

0 kommentar(er)

0 kommentar(er)